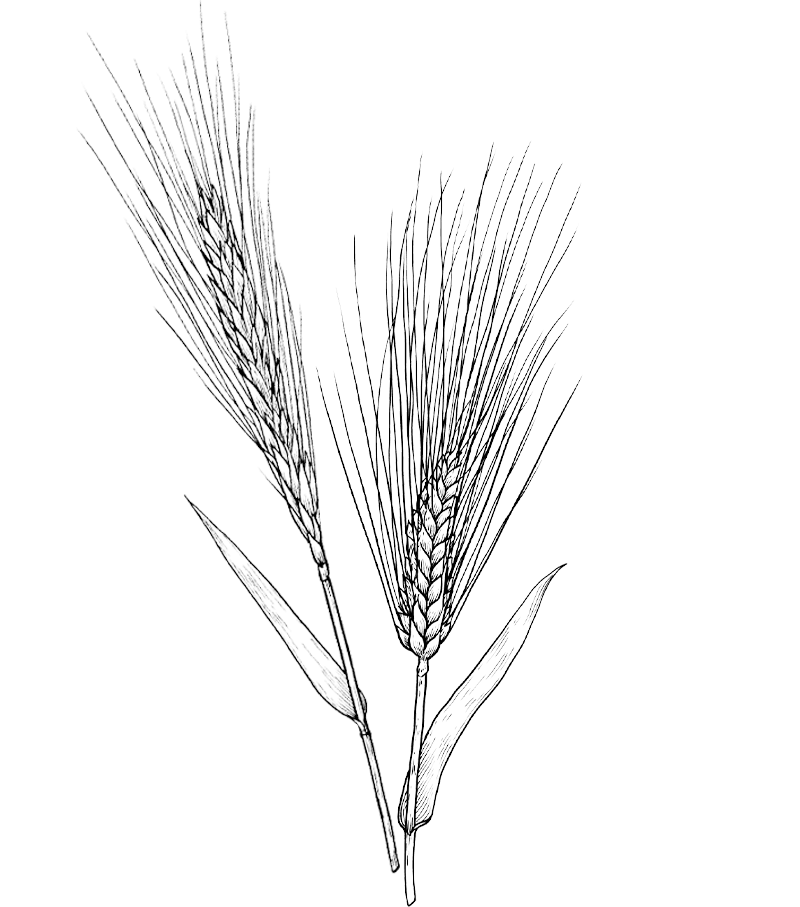

from the month of June, the grain is ripe and ready for harvesting.

the best grains are selected and carefully cleaned of foreign substances (such as straw).

the beans are rehydrated to increase their humidity. This is to ensure a better separation of the peel in the next step, the grinding

is the most important part of the flour producing process. The grains are broken up to extract their “heart”, creating a by-product of broken grains and flakes.

Durum wheat flour is created from this process. Soft wheat flour, on the other hand, depends upon multiple grinding to refine and lighten its consistency.

the flour is sieved which results in a reduced particle size. The most refined flour is type 00 flour.

At this point in the process, the semolina is ready; to refine the wheat flour even more, you can proceed with another step: the re-grind.

repeat grinding gives a more refined result.

Milling is a grinding process which transforms the kernels of the cereals into flour. The universally-recognised excellence of the European and Italian milling sector comes from centuries of experience and mastery. This means: the selection of the best grains and a skilful mix of tradition with cutting-edge technologies to create the production of high-quality flours which meet the specific needs of the users. The high level of responsibility and reliability of European and Italian millers guarantees the quality and food safety of the products.

The current grinding system is the mechanized version of grinding at home in ancient times. Then, the grains of wheat were crushed manually with a roller on a flat stone. Later this was replaced by the force of water on a wheel. Until the discovery of electricity, mills were always located next to waterways. The milling process has evolved from the days of grinding the wheat between two large stone wheels (although this process does still occur in a few mills), to the modern roller mill, consisting of two cast steel rollers set slightly apart from each other. The top roller runs at a slightly faster rate to the lower roller; when wheat passes through, it creates a shearing action, opening up the wheat grain.

The fragments of the grain are separated by being passed through a complex arrangement of sieves. White endosperm particles are then channelled into a series of smooth reduction rolls for final milling into white flour. As well as flours suitable for the production of bread, pasta and other products, the grinding of wheat provides bran, which is also used in animal feed.

When the grain arrives at the mill, it is inspected and weighed to ensure it meets the minimum quality standards. Each stage of reception, consignment and bulk storage in silos is controlled and recorded by a computerized traceability system, which allows the entire production chain of each batch of flour to be reconstructed and tracked.

The grains are cleaned through two processes to remove any foreign mineral and vegetable substances (such as grains of other cereals, straw, etc.) using new cutting-edge technologies, such as optic sorters. After the grain has been cleaned, the milling begins.

Although the grinding process has remained substantially unchanged over time, technological advances ensure food safety and hygiene standards are guaranteed as well as producing flours with different characteristics responding to the demands of the market.

Today the range of available flours is wider than ever thanks to the miller’s ability to identify, select, mix and transform the best varieties of wheat, whatever their origin and characteristics, in order to produce flours suitable for different uses.